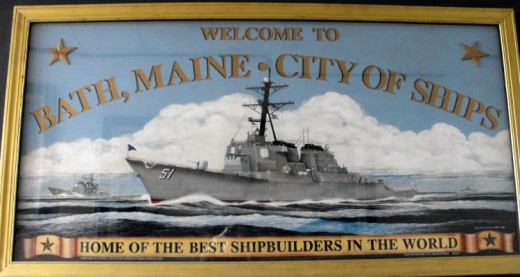

General Dynamic’s Bath Iron Works — BIW for short — builds Navy destroyers. Its cranes tower over the city. I mean that literally, as they’re visible from downtown and from just about any street in Bath. Closer up, the shipbuilding facilities are enormous — an awe-inspiring sight. If you want details about the mega-structures that make up the shipyard, take a look at the BIW web site.

General Dynamic’s Bath Iron Works — BIW for short — builds Navy destroyers. Its cranes tower over the city. I mean that literally, as they’re visible from downtown and from just about any street in Bath. Closer up, the shipbuilding facilities are enormous — an awe-inspiring sight. If you want details about the mega-structures that make up the shipyard, take a look at the BIW web site.

Bath Iron Works was founded by Thomas Worcester Hyde in 1884. Hyde initially manufactured commercial and maritime castings, but soon turned to building steel vessels — helping Bath recover from the end of the wooden-ship era (more on Bath’s booms and busts in a minute).

But it was before and during World War II that Bath Iron Works became a powerhouse:

“Beginning in 1934 Bath Iron Works completed 83 destroyers and destroyer-minelayers by the end of World War II — the largest destroyer output of any builder,” notes the Destroyer History Foundation (yes, there is such a group).

As recently retired Bath planning director Jim Upham adds, “During WWII, Bath Iron Works built more ships than did all of Japan.”

Want to see a lesson in long-term productivity in defense of our nation? Just scroll down and down and down the Wikipedia entry on Bath Iron Works.

Over the past two decades, BIW has been cranking out the Arleigh Burke class of destroyer.

According to Portland Press Herald reporter J. Hemmerdinger (in “Assessing the future for Bath Iron Works,” Sept. 25, 2011) “the shipyard has built 33 Arleigh Burkes since the 1990s,” slightly outpacing its chief competitor, the Ingalls shipyard in Pascagoula, Mississippi. But production of this class of naval ship, if not yet at its end, is slowing down.

As Hemmerdinger notes, “most experts expect that continued demand for new destroyers will ensure the long-term stability of the company.” But that’s no sure thing, with potential heavy defense cuts in the offing.

Why is Bath Iron Works so critical for Bath — and for the State of Maine?

As Down East magazine’s Joshua F. Moore explained (in “City of Surprises,” May 2010), Bath Iron Works “is Maine’s largest private employer, running three daily shifts comprising some 5,640 employees (about 9 percent of them Bath residents). It is also Bath’s largest taxpayer, contributing … more than a quarter of the overall tax base.”

That’s part of what Upham also stressed to us — that is, about a dozen planners attending the Northern New England APA conference — during a tour of his hometown.

Upham recounted that over the course of more than 250 years hundreds of shipbuilders have called Bath home. Since the first ship rolled down the planks in 1743, roughly 5,000 vessels have been launched from here. Indeed, in 1854 Bath was ranked third nationally after Boston and New York City in the volume of wooden-hulled vessel production.

But then Bath’s fortunes plummeted — as the wooden-hull era came to an end — to be followed, as earlier noted, by Bath Iron Work’s emergence as a steel vessel builder.

Many of the stately houses you’ll find in Bath, and the fine commercial buildings lining Front Street, owe their presence to the wealth accumulated by Bath’s shipbuilders.

Shipbuilding and Bath have long been inseparable — and Bath justifiably calls itself “The City of Ships.”

But, as Jim Upham described, one of the consequences of this inseparability is that you’ll likely encounter a boom and bust cycle (though hopefully, not just the bust part).

Over the past decade, BIW has generally been doing well, with major Navy contracts in hand. Yet, as a BIW spokesman acknowledged just two weeks ago — in announcing a relatively modest 88 layoffs — job cuts can be required because of the “unfortunate cyclical nature of shipbuilding and balancing needed resources against work in hand.”

Even with a hefty payroll of close to 6,000 employees today, that’s still just half the number who worked at Bath Iron Works in the 1980s. What would happen if BIW really took a hit?

In the meantime, as Upham noted, “people plan their lives around 3:30 pm, when the shift changes at Bath Iron Works” and thousands of workers pour out of the shipyard.

Next week, in part II, we’ll focus on Bath’s downtown and on what makes this small city such a distinctive place.

Side note: Here in Northwestern Vermont — where the PlannersWeb offices are located — we have a fairly diversified economy. Yet whenever our region’s largest employer, IBM, starts talking about layoffs at its large Essex Junction facility, everyone gets very nervous. I can only imagine what it would be like having a single dominant employer — especially in a small city.

We’d welcome comments from any of you who live in communities dominated by a single large employer. How does your community deal with this kind of heavy dependence?